Table of Contents

The leather industry

Leather is a highly desirable material, which is available in great abundance since it is a derivative of the ever-flourishing meat industry. There are many types of leather to choose from, each with its own unique characteristics. The animals’ rawhides (usually from cattle) or skins (from other animals) go through a sophisticated manufacturing process, in order to produce various types of leather. This process can be factory-based (heavy industry) or home-based (cottage industry), with equally satisfying results. This means that manufacturing all these types of leather has become a very versatile industry, which can take place even in the smallest of villages around the world.

The production of leather has a heavy economic, social and environmental impact all around the globe, with many leather-based production villages scattered throughout the world, and quite a few large manufacturers. Respect towards human and animal rights, the presence of women in the workforce, fair worker wages, and dealing with the pollution that stems from factory farms and tanneries are just some of the issues that have been raised, regarding the leather production industry. It is important to make socially responsible decisions when buying leather products and to always try to support businesses who act responsibly, ethically and morally, by providing good working environments for their workers and by making viable decisions that ensure their sustainability, while protecting the environment.

Nowadays, leather is used in a multitude of products, ranging from key chains to large pieces of furniture, and the leather industry is growing rapidly because of the market’s constant, urgent need for material.

Common uses for all types of leather

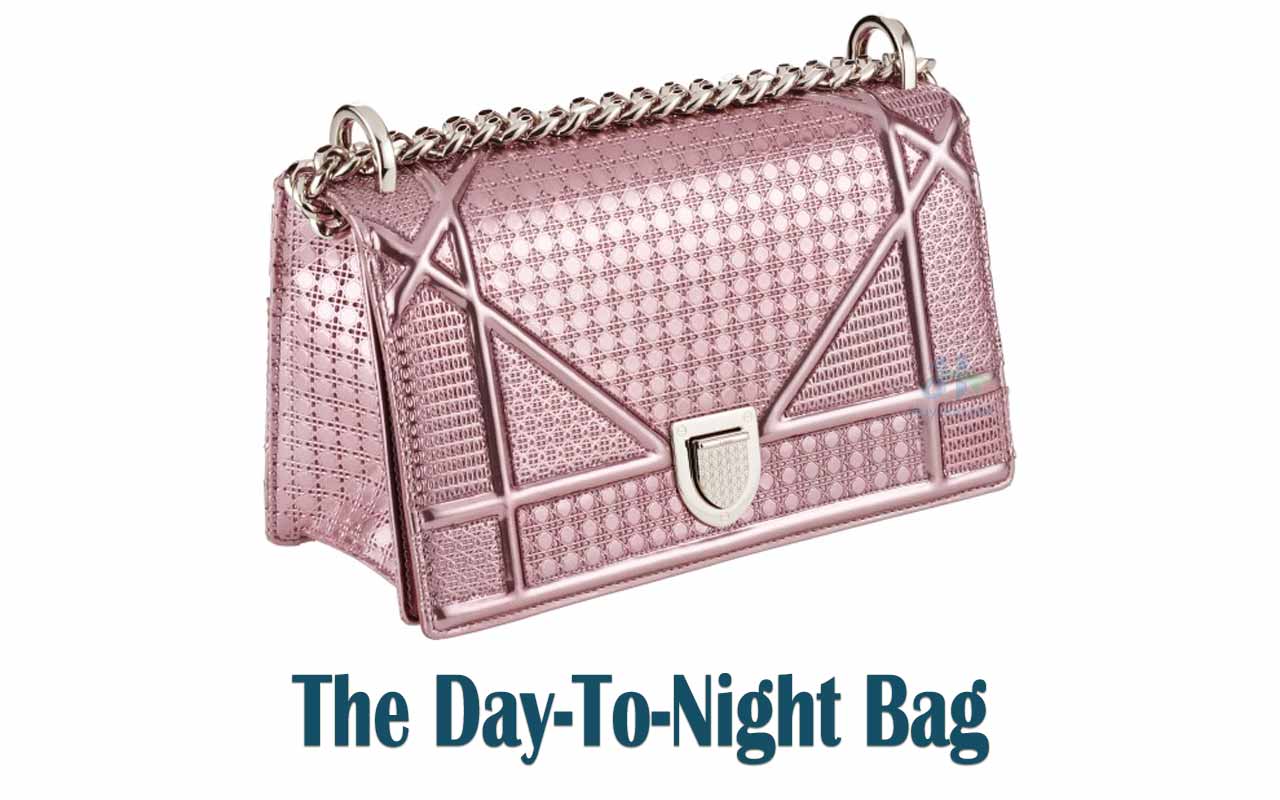

Leather is often used in clothing items, shoes, and accessories, such as bags, belts, and hats, because of its soft, high-quality feel, and classy appearance. The best clothes, accessories, and shoe brands are always looking to use the finest raw materials to produce their high-quality goods, and some of them seem to prefer Italian leather because it has traditionally been considered insurmountably superior. However nowadays, there are quite a few other sources of raw material of equal or even higher quality, and many types of leather to choose from, for each and every particular manufacturing need.

Pieces of furniture are often upholstered in various types of leather since it is a very durable and breathable material that ages beautifully. Because of its resistance to dirt and stains, leather is often the best choice for everyday use of chairs and seats, especially if there are young children in the household. Being such a highly sought-after material, though, means that leather sofas and couches are quite a bit more expensive than their fabric-upholstered counterparts. Leather is a very popular choice for luxury car seats, as well.

Bookbinding, which is the process of putting the pages of a book together and covering them with a leather layer, can also make use of leather. Premium book editions feature leather covers, which give them a stern, classic look. Leather-bound tomes are often thought of as symbols of status.

Factors that affect the leather quality

The animal whose raw hide or skin will be used

Rawhide from cattle is the most prevalent, but sheep, horses, pigs, goats, and even kangaroos are also regularly used for leather production. The skins of snakes, alligators, crocodiles, ostriches, and other exotic animals – and even fish – can also be used, in order to produce special types of leather.

The life and treatment of the animal

The age and sex of the animal, its place of origin, it is the way of life, its feed and nutrition, and its general health are all factors that play a decisive role in the quality of the end product, for all types of leather.

The tanning process

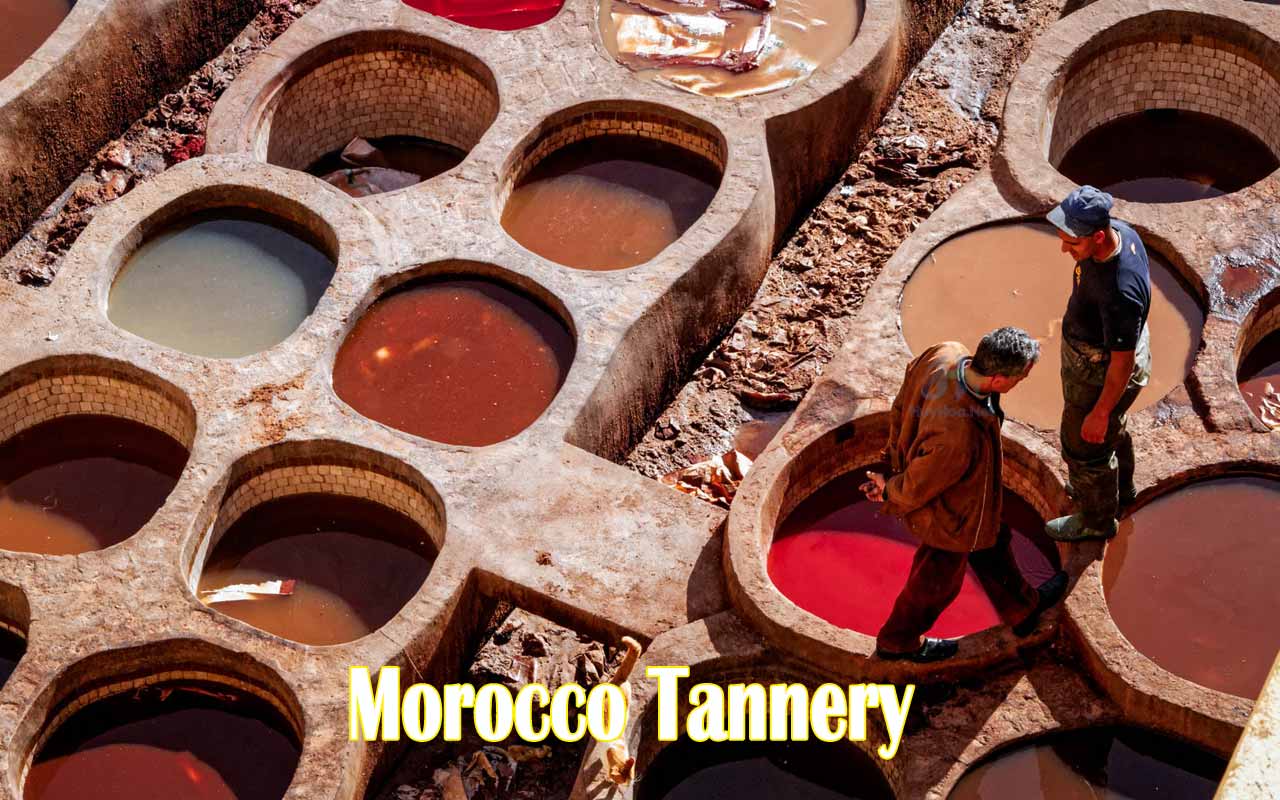

The process that produces leather by treating raw hides is called tanning. It involves submerging the hide in water, in order to thoroughly clean and soften it. Next, the hide is cured with salt, in order to greatly reduce its moisture content, a method that protects it from bacterial growth and allows the cured hides to be preserved for a long time without deteriorating.

When the cured hide is ready to be tanned, it is soaked in water once more in order to remove the excess salt. The hide is treated with the milk of lime by going through the process of liming to weaken the hair, keratin proteins, and other unwanted materials from the hide. It undergoes multiple treatments until the PH of the collagen in the skin is at the optimal levels for the completion of the tanning process.

There are various types of the actual tanning process, which create numerous types of leather;

Vegetable tanning

Vegetable tanning uses tannins and other materials, which are commonly found in plants. The plants’ leaves, roots, fruit, bark can all be used to produce vegetable tannins, which produce supple, flexible leather, with naturally brown shades. The most commonly used tree barks are those of oak, chestnut, mangrove, acacia, and others. Vegetable-tanned kinds of leather are primarily used for upholstering furniture and luggage.

Herbal tanning uses tannins – substances naturally extracted from trees such as oak, chestnut, etc. Tannins bind proteins in the skin and coat them, making them less water soluble and resistant. bacterial attack. This tanning process also causes the piece of leather to discolor and can be used for many purposes.

+ Advantages: herb-tanned leather is suitable for carving/carving complex and delicate motifs, thick leather is still flexible and elastic. Above all, this method is very friendly to the environment and people, does not cause any negative impact on the environment and reduces the pressure on waste. In addition, this type of leather is often used for unique, delicate products that are tailored to each specific need. For example, hand-carved, engraved and colored.

Cons: poor heat resistance. Herb-tanned leather may shrink or crack if exposed to heat. And leather with this method will be less diverse than leather with chromium. And as analyzed above, this type of leather requires a longer time to complete as well as a higher cost than chrome leather.

Chrome tanning

Considered the most effective tanning chemical, chromium sulfate is used as the main chemical in the chromium tanning process.

This is a method widely used in the industry today, with the advantage of good price and can be expanded to many options to create the best quality leather pieces, suitable for different needs. . Another advantage of this tanning process is that the piece of leather after tanning is water-resistant, heat-resistant, soft, and easily dyed.

The downside of this method is that it is not environmentally friendly and has the potential to cause some problems for tanners, especially those who are sensitive to chemicals.

Normally, chromium tanning takes about 2 days while herb tanning can take up to a month. In the market, chromium-tanned leather is sold for only ½ or 1/3 of the price of vegetable-tanned leather.

Involves the use of chromium sulfate in order to transform the cured hide into leather. The distinct blue color of these types of leather that are produced via this method has given them the name ‘wet blue’. Chrome tanning, which takes way less time than vegetable tanning, produces even more supple and more flexible types of leather, which are ideal for bags and clothes.

Aldehyde tanning

This is a method that produces chrome-free types of leather, which are used for products that require a more sensitive approach, such as infant shoes. Aldehyde-tanned leather has a naturally creamy color and is often referred to as ‘wet white’ leather.

There are many other methods of hiding tanning, which utilize additional substances, such as formaldehyde and aluminum salts, depending on the desired attributes of the final products.

Types of leather

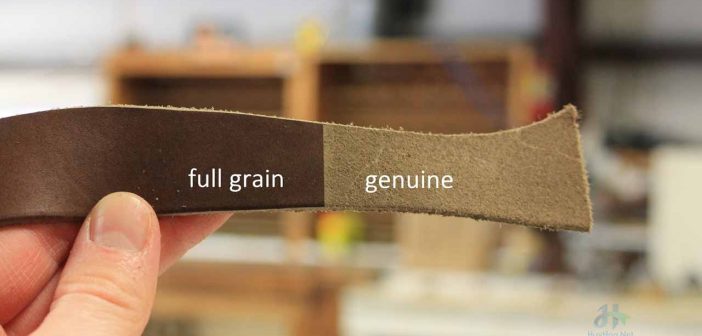

Full-grain leather

Leather that has not undergone sanding, buffing, or any other process to remove any imperfections is called full-grain leather. It is the most durable and strongest of all kinds of leather because it retains the layer of skin which is found just below the hair, giving it breathability and resistance to wear. It develops a beautiful patina over time and is generally used for high-quality shoes and accessories.

It is mainly available in three finish types:

- Aniline leather is colored using transparent dyes, and the grain remains visible and natural. Any imperfections are visible, too, but that adds to the natural look’s allure.

- Semi-aniline leather is covered with pigmented coats of brilliant and transparent colors, which camouflage any blemishes a bit more aggressively. It is a bit more practical to use than Aniline leather, since it has some protection on it, albeit light.

- Napa leather is chrome-tanned, very soft to the touch, and is usually used for furniture, clothing, shoes, wallets, and personal toiletry goods.

Top-grain leather

The second best type of leather, quality-wise, is top-grain leather. It is almost the same as full-grain leather, but with the top few millimeters sanded or buffed off, in order to remove blemishes and imperfections. A topcoat is applied, in order to preserve its beautiful appearance, since top-grain doesn’t develop a patina over time. However, these types of leather are very flexible, soft, and durable, and they are less expensive and easier to handle than their full-grain counterparts.

Nubuck leather is top-grain cattle leather, also known as unprotected, distressed, or naked leather. It has a buttery feel and resembles suede.

Corrected-grain leather

When a hide doesn’t fit the standards to be turned into full or top-grain leather, it is generally used to produce corrected-grain leather. An artificial grain is stamped onto it, and it is often dyed in order to hide any blemishes or mistakes in the grain stamping process. It is used as a cheaper alternative to other types of leather.

Split leather

Split leather is made of layers of hiding that are leftover, during the production of full or top-grain leather. These layers can be divided into two splits, the middle split, and the flesh split. If the middle split is thick enough, it can be divided again into two (or even more) splits. An artificial topcoat is often used to seal these types of leather, in order to give them an appearance resembling that of top-grain leather and to protect them from wear. These types of leather are also used to make suede, which is fuzzy and soft on both sides.

Other types of leather

- Finished leather, also known as patent leather, has a high gloss finish. It typically has a heavy plastic coating.

- Pigmented leather has a more consistent color and it sports a glossy topcoat.

- Belting leather, which was originally used to make machinery belts, is full-grain leather that is very stiff and durable.

- Vachetta leather is often used as trimming on handbags and other accessories.

- Pull-up leather, which is stretchy and is used in fashion clothing.

- Deerskin is harder and tougher than other types of leather and is often used to make jackets and overcoats.

- Fish leather, which is tanned just like animal hides, comes in many colors and textures and has many uses.

Things to be wary of when buying leather products

There are a few types of material that are often marketed as leather when in actuality they are not. They are often presented as great deals or discounts, but their production cost is way lower than that of real leather. Some of them are actually made from byproducts of the tanning process. These materials include -but are not limited to;

Bonded leather is made of scrap hide pieces which are byproducts of real leather production. These pieces are shredded and ground into even smaller pieces, which are then laid out flat and stuck to each other with a thick layer of polyurethane (plastic). Bonded leather contains (at least) about 17% of actual leather.

Bonded leather is also known by several other names. When shopping for leather furniture or clothing, if you see one of the names below, it’s Bonded Leather. Learn more about bonded leather here

- Bonded Leather

- LeatherSoft

- Faux Leather

- Vinyl

- Reconstituted

- Composit

Bicast leather the original formula by Bayer was strong and expensive. Bicast leather is made of layers of split hide which are completely sealed and coated with polyurethane and then embossed. It is essentially more plastic than leather, and it is generally used in shoe production. The material is easier to clean, but harder to repair than real leather.

Leather match; is the practice of using real leather on a piece of furniture for all the surfaces that can be touched and other (cheaper) materials for the rest of its surfaces. Sometimes the touchable parts are covered with top-grain leather, and the rest are covered with splits so that the manufacturers can still claim their product to be upholstered in 100% leather.